5 Ways Sensors Increase Safety and Reduce Maintenance Costs in Infrastructure Projects

Infrastructure like bridges, tunnels, and buildings is designed to last for decades — but time, weather, and wear take their toll. Engineers today rely on sensors for infrastructure monitoring to ensure that these critical structures stay safe, reliable, and cost-effective to maintain.

Here are five ways advanced sensor technology — like ElastiSense Sensor Technology’s solid-state displacement sensors — is transforming the way we manage infrastructure.

1. Real-Time Condition Monitoring

With modern sensor technology, engineers can monitor bridges, tunnels, and dams in real time. This continuous flow of data allows them to detect shifts, cracks, or displacement before they become safety concerns — replacing reactive maintenance with proactive insight.

2. Early Warning Systems for Structural Issues

Traditional inspections can miss gradual changes that indicate trouble ahead. Sensors make it possible to identify early warning signs — like small cracks or unexpected movements — and act before a minor issue becomes a costly or dangerous failure.

3. Lower Maintenance Costs

Manual inspections are time-consuming, expensive, and sometimes risky. By deploying sensors for infrastructure monitoring, maintenance teams can reduce site visits, focus resources where they’re truly needed, and avoid unnecessary downtime.

4. Enhanced Safety for People and Assets

When sensors are in place, engineers and operators can work with confidence. Automated alerts and data visualization tools make it easy to assess risks remotely, protecting both the structure and the people who depend on it.

5. Extending the Lifespan of Infrastructure

By identifying stress, displacement, and other structural challenges early, sensor data helps extend the lifespan of infrastructure — supporting predictive maintenance strategies that save millions over time while improving sustainability.

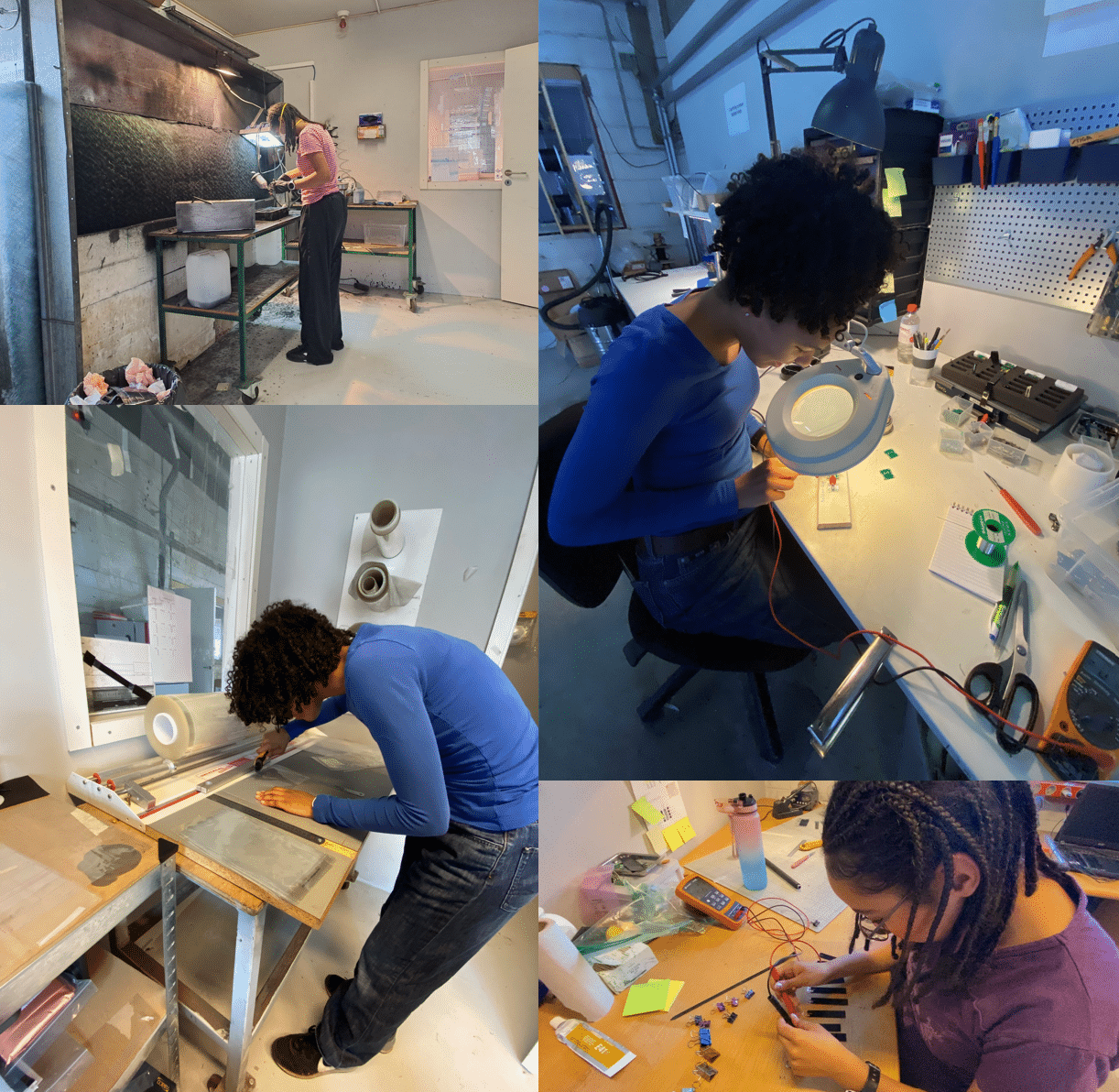

Smarter Monitoring with ElastiSense Sensor Technology

At ElastiSense, we’re proud to contribute to safer, smarter infrastructure with our solid-state displacement sensors. Built for harsh environments and long-term reliability, they deliver the data engineers need to make informed decisions and keep the world’s infrastructure standing strong.

👉 Learn more about our sensors for infrastructure monitoring here: https://elastisense.com/products-sensor-solution/structural-health-monitoring/