Embracing Digitalization: The Role of Structural Health Monitoring in Safeguarding Bridges.

In the rapidly evolving landscape of infrastructure management, ensuring the safety and longevity of bridges is paramount. Bridges, serving as critical links in transportation networks, endure relentless exposure to environmental stresses and heavy traffic loads. Hence, the need for vigilant monitoring and maintenance practices cannot be overstated. With the advent of digitalization, the field of Structural Health Monitoring (SHM) has emerged as a transformative solution, offering real-time insights into the condition of bridges and facilitating proactive maintenance strategies.

Understanding Structural Health Monitoring

Structural Health Monitoring (SHM) is a multi-disciplinary field that integrates various sensing technologies, data analytics, and communication systems to continuously monitor the condition of structures. In the context of bridges, SHM involves the deployment of sensors to collect data on parameters such as vibrations, strain, temperature, and corrosion levels. These sensors are strategically placed throughout the bridge structure to capture comprehensive information regarding its performance and structural integrity.

The Digitalization Paradigm

Digitalization has revolutionized traditional approaches to infrastructure management by leveraging advanced technologies to enhance efficiency, accuracy, and safety. In the realm of bridge monitoring, digitalization has enabled the seamless integration of sensor networks, data analytics platforms, and communication systems, fostering a holistic ecosystem for real-time monitoring and analysis.

Key Components of Digitalized Structural Health Monitoring Systems

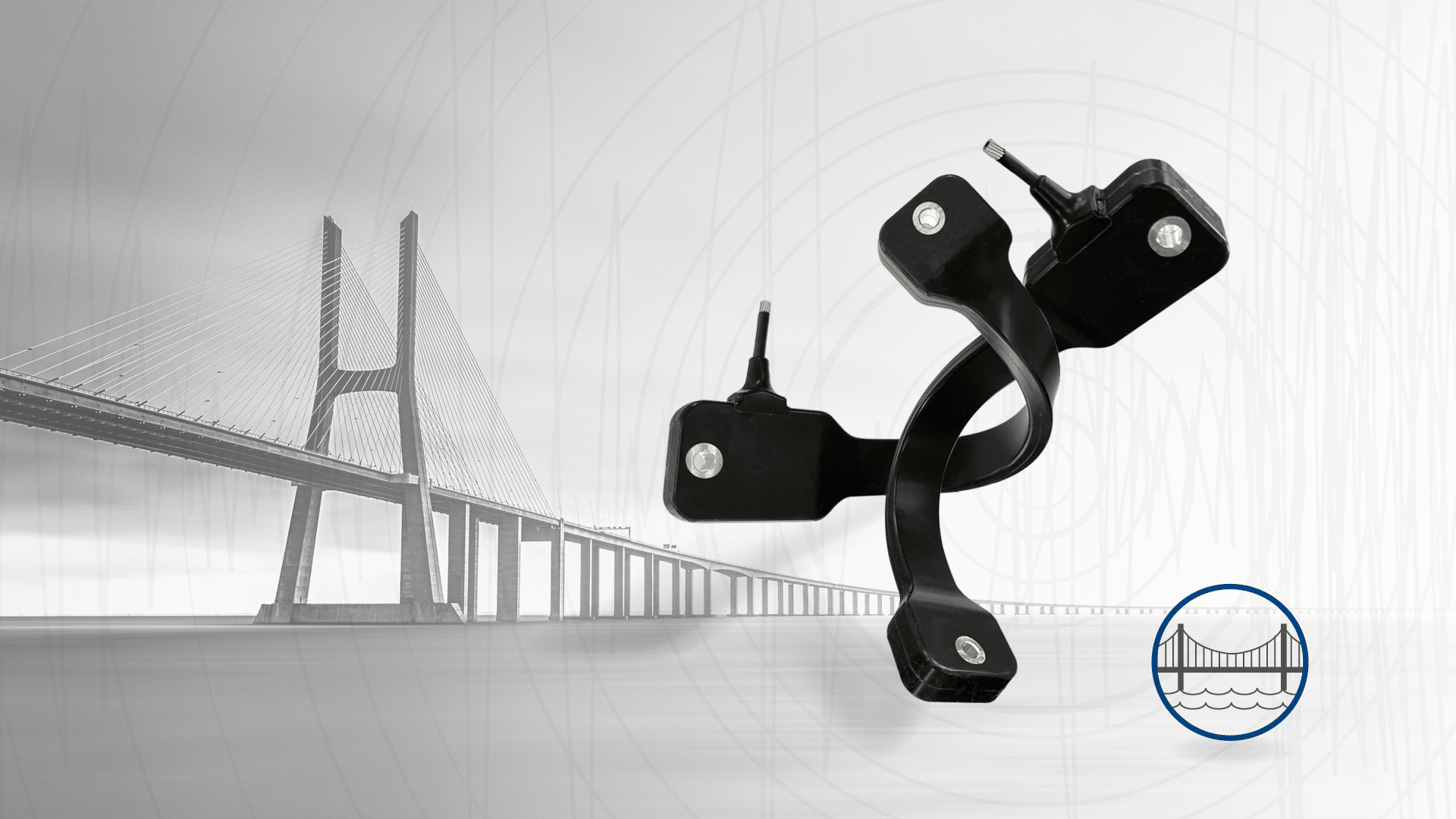

- Sensor Technologies: Advanced sensor technologies, including accelerometers, strain gauges, and fiber-optic sensors, serve as the backbone of SHM systems, capturing real-time data on structural behavior and performance.

- Data Acquisition and Processing: High-speed data acquisition systems collect sensor data at regular intervals, while sophisticated algorithms process and analyze this data to identify anomalies, deviations from expected behavior, and early signs of structural deterioration.

- Wireless Communication: Wireless communication protocols enable seamless transmission of sensor data to centralized monitoring centers, allowing engineers and stakeholders to access real-time information from remote locations.

- Data Analytics and Predictive Modeling: Data analytics techniques, such as machine learning and predictive modeling, enable the identification of patterns and trends within large datasets, facilitating predictive maintenance strategies and proactive decision-making.

- Decision Support Systems: Integrated decision support systems provide engineers with actionable insights and recommendations based on real-time data analysis, empowering them to implement timely interventions and optimize maintenance schedules.

Benefits of Digitalized Structural Health Monitoring

- Early Detection of Structural Issues: By continuously monitoring key parameters, digitalized SHM systems can detect potential structural issues at an early stage, allowing for timely interventions and preventing catastrophic failures.

- Optimized Maintenance Strategies: Real-time data analysis enables engineers to develop data-driven maintenance strategies tailored to the specific needs of each bridge, optimizing resource allocation and prolonging the lifespan of critical infrastructure assets.

- Enhanced Safety and Reliability: By providing stakeholders with timely information on the condition of bridges, digitalized SHM systems enhance safety and reliability, minimizing the risk of accidents and disruptions to transportation networks.

- Cost Savings: Proactive maintenance and targeted interventions based on real-time data analysis help minimize repair costs and extend the service life of bridges, resulting in long-term cost savings for infrastructure owners and operators.

Challenges and Considerations

Despite the numerous benefits offered by digitalized SHM systems, several challenges must be addressed to maximize their effectiveness:

- Data Security and Privacy: Safeguarding sensitive sensor data from cyber threats and ensuring compliance with privacy regulations is essential to maintain the integrity and trustworthiness of SHM systems.

- Interoperability and Standardization: Establishing common standards and protocols for data exchange and interoperability among different SHM systems is critical to facilitate seamless integration and collaboration across infrastructure networks.

- Cost and Scalability: While the cost of sensor technologies and data analytics platforms has decreased in recent years, ensuring the scalability and cost-effectiveness of SHM systems remains a key consideration for infrastructure owners and operators.

Conclusion

In an era defined by rapid technological advancements and digital transformation, the adoption of digitalized Structural Health Monitoring (SHM) systems represents a paradigm shift in bridge maintenance practices. By harnessing the power of advanced sensor technologies, data analytics, and communication systems, these systems empower engineers to monitor bridges in real-time, detect potential issues early, and implement proactive maintenance strategies. As we continue to embrace the digitalization of infrastructure management, the widespread adoption of SHM systems will play a pivotal role in safeguarding bridges, enhancing safety, and ensuring the resilience of transportation networks for generations to come.

Learn more about bridge monitoring right here, or contact us if you wish to discuss specific projects