IoT has become a bit of a buzzword today, but what does it really mean? Obviously, the definitions vary, but we found this definition which sums up pretty well what the basic understanding of IoT is: “The Internet of things (IoT) describes devices with sensors, processing ability, software and other technologies that connect and exchange data with other devices and systems over the internet or other communications networks.” The definition describes IoT as “devices with sensors”, which pretty much rules out our product (the DS sensor) because that is, in fact, a sensor! This explains why we typically describe our sensors as “IoT ready”, because that is exactly what they are.

Let us explain:

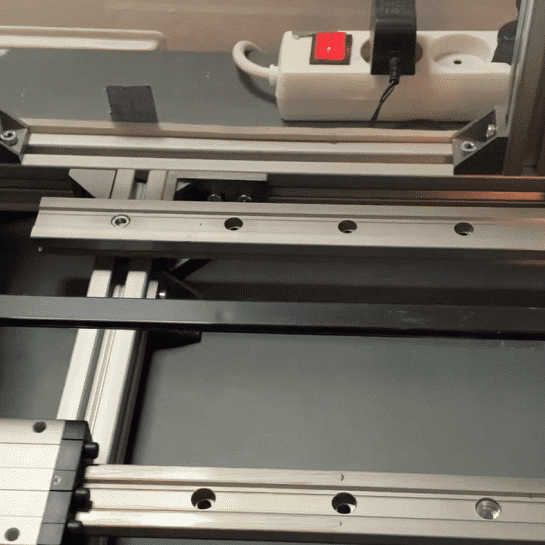

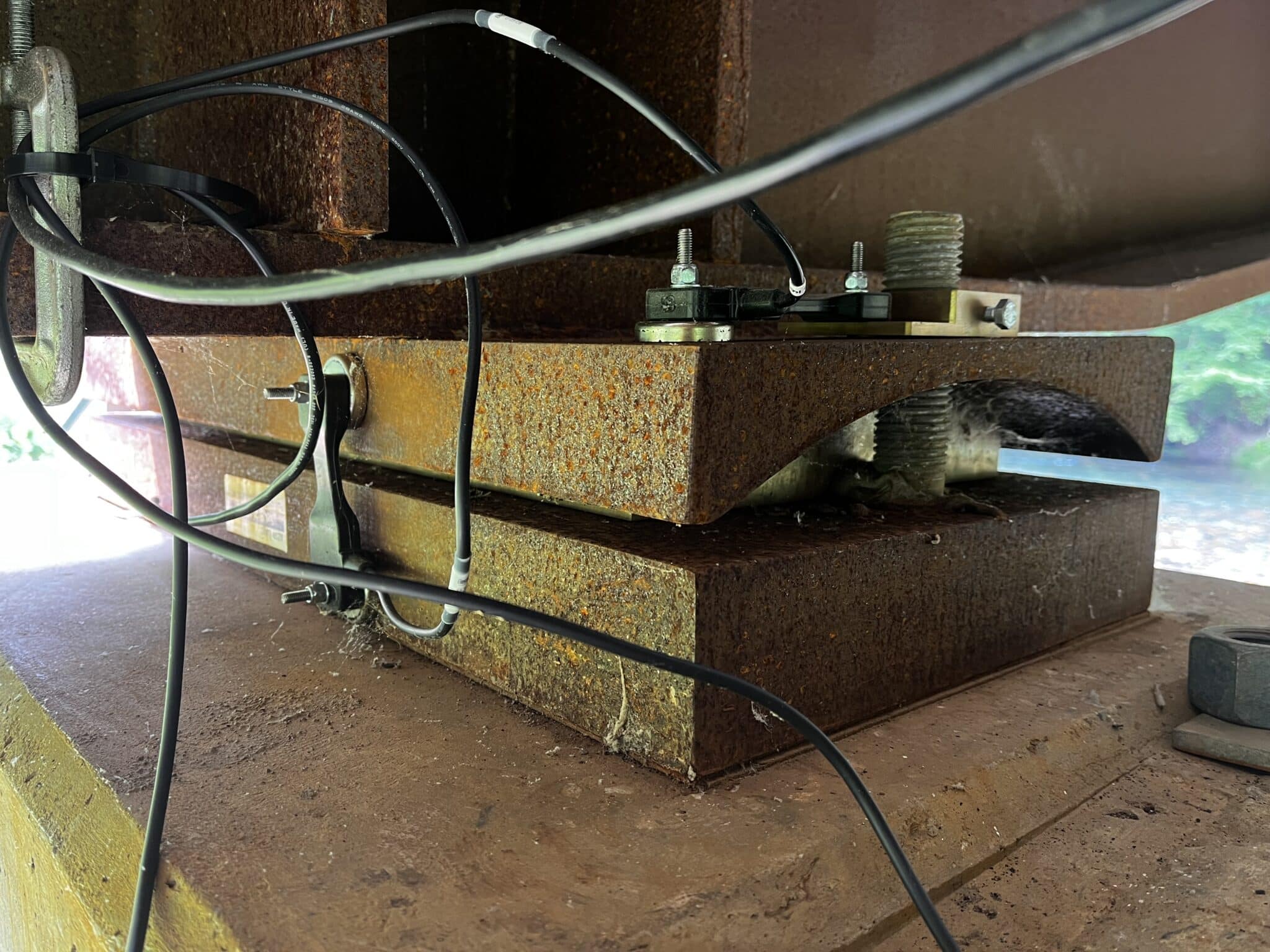

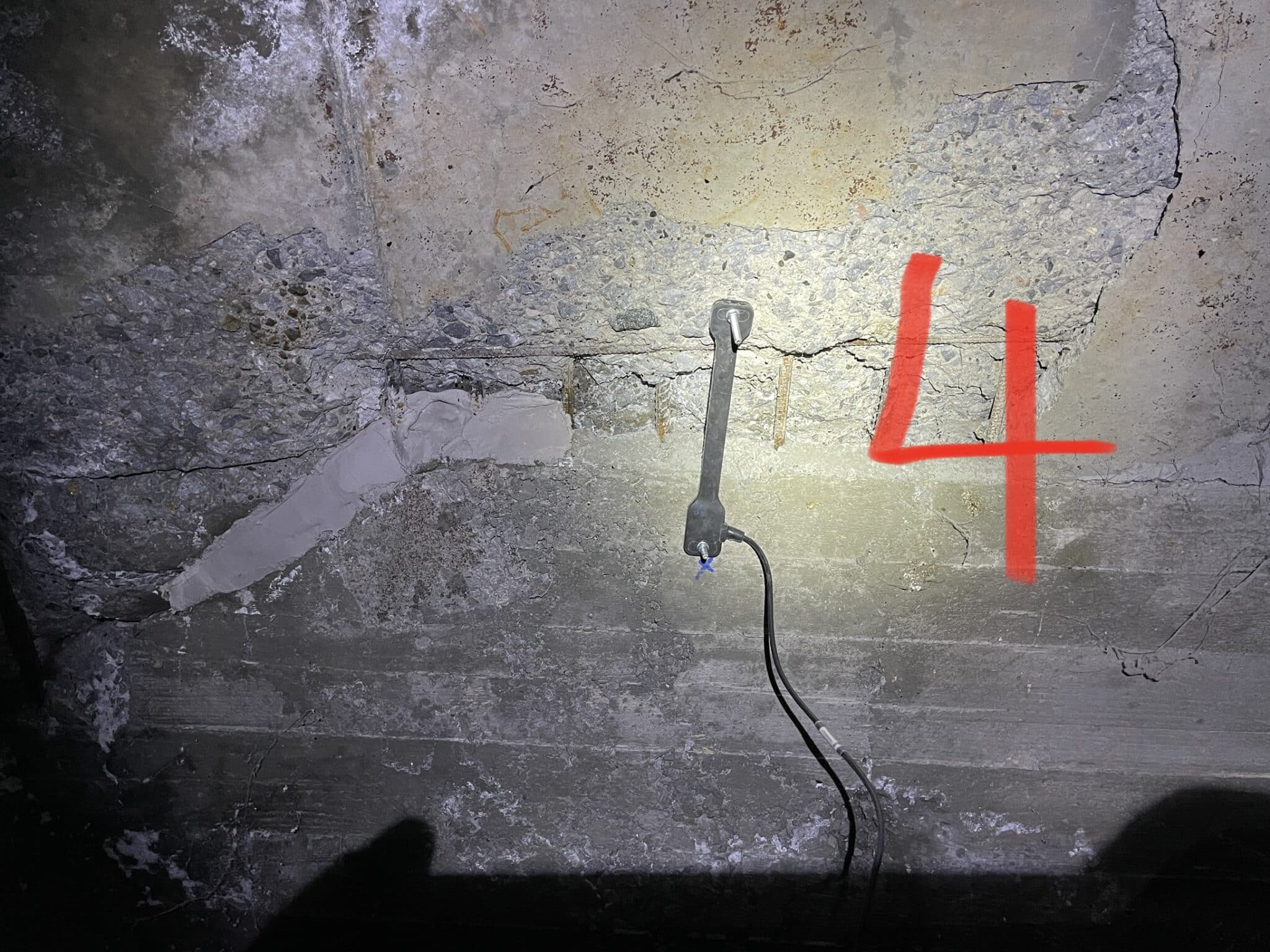

A DS sensor mounted on a bridge, a building a hillside, a stamping machine, a mining train, an excavator, a packaging machine, a tank, or whatever structure, machine, or application you can imagine, basically just detects movement through influence on the sensor itself. If the crack in the concrete on the bridge expands, it simply pulls the two ends of the sensor from each other, thus changing the data coming from the sensor. This data is typically transmitted directly to a sensor node or datalogger which then sends the data to the receiver. If this data is transmitted to the receiver through the internet, for example through a cloud solution, it becomes IoT. This is exactly what our sensors are built for and exactly what makes them IoT ready. Add to that the option of running the sensor on battery power, you can monitor on displacement or movement in remote locations, with no power supply, and pick up the data wherever you are.

All our DS Sensors are born IoT ready, and the battery solution is an add-on feature, also available for all DS sensors.

Don’t hesitate to reach out if you want to know more or if you believe IoT-ready sensors can ad value to your application.